Technical equipment of the laboratories

Additive manufacturing

Microstructure investigations

Scanning electron microscope (SEM)

The scanning electron microscope (Philips XL 30, LaB6, 30kV, see following picture) is equipped with a secondary electron detector (SE detector, picture REM2) for imaging the topography (e.g. fracture surfaces) and a backscatter electron detector (BSE detector, picture REM2), e.g. for examining metallic plane ground samples.

For the measurement of the grain orientation of crystalline metallic materials according to the EBSD method, a measuring device with corresponding software (OIM) is available.

The SEM also contains an additional device (EDX detector, see above image) with associated evaluation software for micro-range analysis, which allows qualitative and quantitative statements regarding the local composition. In addition, this software enables the recording of element distribution images.

Microscopes

Stereo microscope

A stereomicroscope (Leitz WILD M3Z) is available for the macroscopic observation of objects under examination. Digital image acquisition up to a magnification of 40:1 is possible with this microscope equipment.

Reflected light microscope

Reflected light microscopes from Zeiss (Axioskop2) and a Leica MC170HD camera allow the examination of the microstructure of flat polished and etched samples up to a magnification of 1000:1.

Olympus 3D Laser Measuring Microscope LEXT OLS 4000

The LEXT OLS4000 3D laser measuring microscope is designed for 3D measurement and roughness measurement in a nanometer range. Magnifications from 108x – 17,280x are possible

Polytec 3D-Scanning Vibrometer (PSV 400/500 3D)

The detected vibration shapes and eigenmodes help with acoustic and structural dynamics issues, ultrasonic analyses, FEM validation and even non-destructive testing.

Thanks to simultaneous measurement of in-plane and out-of-plane data, the PSV-3D enables meaningful operational vibration shape analyses and finite element simulation models to be validated – for frequencies from DC to 25 MHz and vibration velocities from 0.01 µm/s to 30 m/s.

Micro hardness tester

Small load Vickers hardness tester

Struers Duramin-1/-2

Measuring range HV0.5-HV2

X-ray diffractometer

Panalytical X’Pert

The following X-ray fine structure investigations can be carried out:

Qualitative and quantitative phase analysis

Identification of unknown substances and determination of phase fractions in mixtures.

Crystal investigations

Determination of crystal structure/type, size of crystal lattice, lattice constant, lattice parameters.

Residual stress measurement

Mechanical stresses without the influence of external forces. The stress measurement is based on the determination of lattice strain distributions.

Texture determination

Textures can be created by drawing and rolling. (Anisotropy – directional arrangement of crystals).

Determination of the preferred orientation of individual crystals

Measurements can also be carried out in different gas atmospheres and at 1500°C.

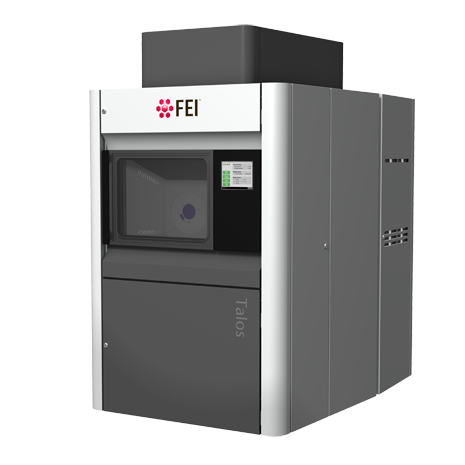

Focused Ion Beam (FIB)

The ultra-high resolution Focused Ion Beam system (FIB) (Helios Nanolab 600, see image below) is used for 3D material characterisation, defect analysis and nanocharacterisation. The electron optics has a resolution of 0.9nm @ 15kV and 1.4nm @ 1kV and is equipped with an ultra-high-brightness field emission source with magnetic immersion lens and SE and RE Inlens detectors. The ion optics have a resolution of 5nm @ 30kV. Through the ResolveRT software package, it is possible to create 3-dimensional image reconstructions from 2-dimensional sections.

Analysis laboratory

Hydrogen analysis

The H836 element analyser is designed to measure hydrogen, the hydrogen content of inorganic material, ferrous and non-ferrous alloy refractory materials. It uses the internal gas fusion technique.

The unit has a special touch screen system based on Microsoft Windows. This system gives you complete access to analysis settings, diagnostics and much more without taking up much space.

Carbon and sulphur analysis

CS analytical system for inorganic solids with a very wide range of applications

– Robust universal design for use “on site” as well as in high-tech laboratories

– C/S measurements from 1-2 ppm to 100 % (depending on the sample weight)

– Control via DSP controller and/or Leco Windows software

– Fully automatic oven cleaning with dust trap cleaning (Leco exclusive!)

– High frequency combustion at 2300 °C

– Analysis time of approx. 40 seconds

– (Option) Autoloader for 20 positions with quick loading device and further automation options

Emission spectrometry

The metal analyser, emission spectrometer from the company Spectro Analytical Instruments GmbH & Co. KG in Kleve (SPECTROMAXx), meets the diverse requirements, especially with regard to the measurement variety of different alloys, which are used within the Institute for Materials Technology in the context of research projects, damage analyses and other material investigations. The spectral analyser on offer has high-resolution CCD optics that meet the requirements of a modern analysis laboratory and enables the determination of the chemical composition of iron, nickel, titanium and aluminium-based alloys.

High-temperature laboratory

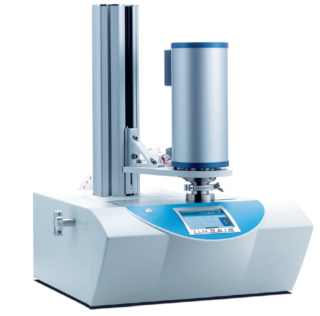

Thermo-gravimetry

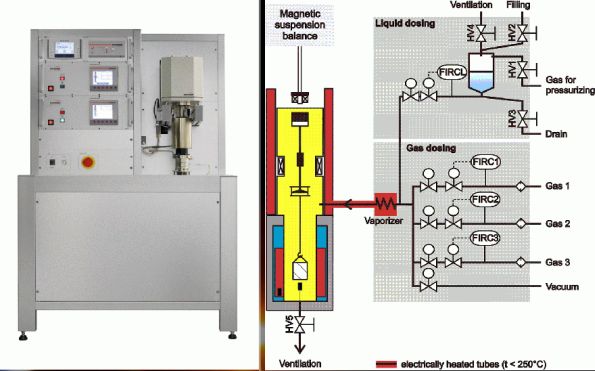

Thermogravimetry in conjunction with a magnetic levitation balance is particularly suitable in highly corrosive ambient atmospheres or whenever the occurrence of volatile gas species is to be expected. In contrast to conventional thermogravimetric systems, a spatial separation of balance mechanics and reactor takes place via a magnetic coupling. The sample is held in suspension by means of a permanent magnet attached to the sample suspension or an electromagnet on the side of the balance and the change in mass is recorded by inductive displacement transducers. The magnetic levitation thermobalance designed by Rubotherm (maximum measuring accuracy 0.1 µg, sample mass up to 25 g) allows fully automatic experiments up to temperatures of max. 1600 °C under isothermal and thermocyclic conditions. In addition to laboratory air, any mixable gas composition as well as vacuum can serve as the ambient atmosphere. The oxygen content can be constantly monitored via a ZrO2 measuring cell.

VHCF Laboratory (Very High Cycle Fatigue)

High frequency fatigue 1kHz

High frequency fatigue 20kHz

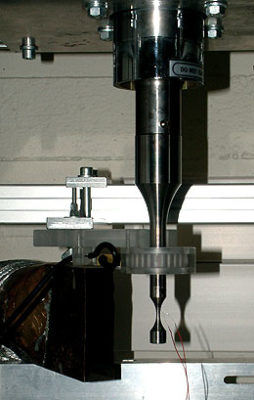

The test rig available at the Institute of Materials Engineering uses ultrasound in the frequency range up to 21.5 kHz to conduct fatigue tests on metallic materials in the resonance range.

Due to the extremely high frequency range, service life ranges of up to 10^10 load cycles can be covered with this method in a test duration that is acceptable in terms of time.

The test stand is a development of the working group of Prof. Mayer at the Boku in Vienna.

The system described is an oscillating system in which the individual components must be tuned to each other in such a way that defined zero crossings of stress and strain are induced at specific, metrologically monitored points in the system. The system is influenced on the one hand by the vibration behaviour of the moving components and on the other hand by the current signals produced by means of an ultrasonic generator and converted into mechanical vibrations by means of a transducer.

Here, sinusoidal high-frequency signals are generated by means of a frequency generator, which are transformed into a mechanical vibration by a piezoelectric converter.

With test stand 1, tests can be carried out under alternating load.

Test bench 2 can be used to work with a preload or threshold load.

Resonance pulsator

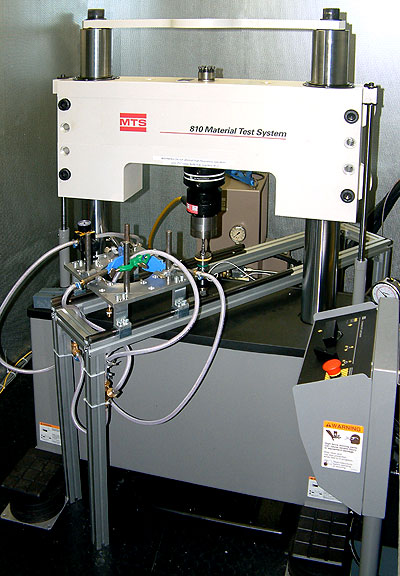

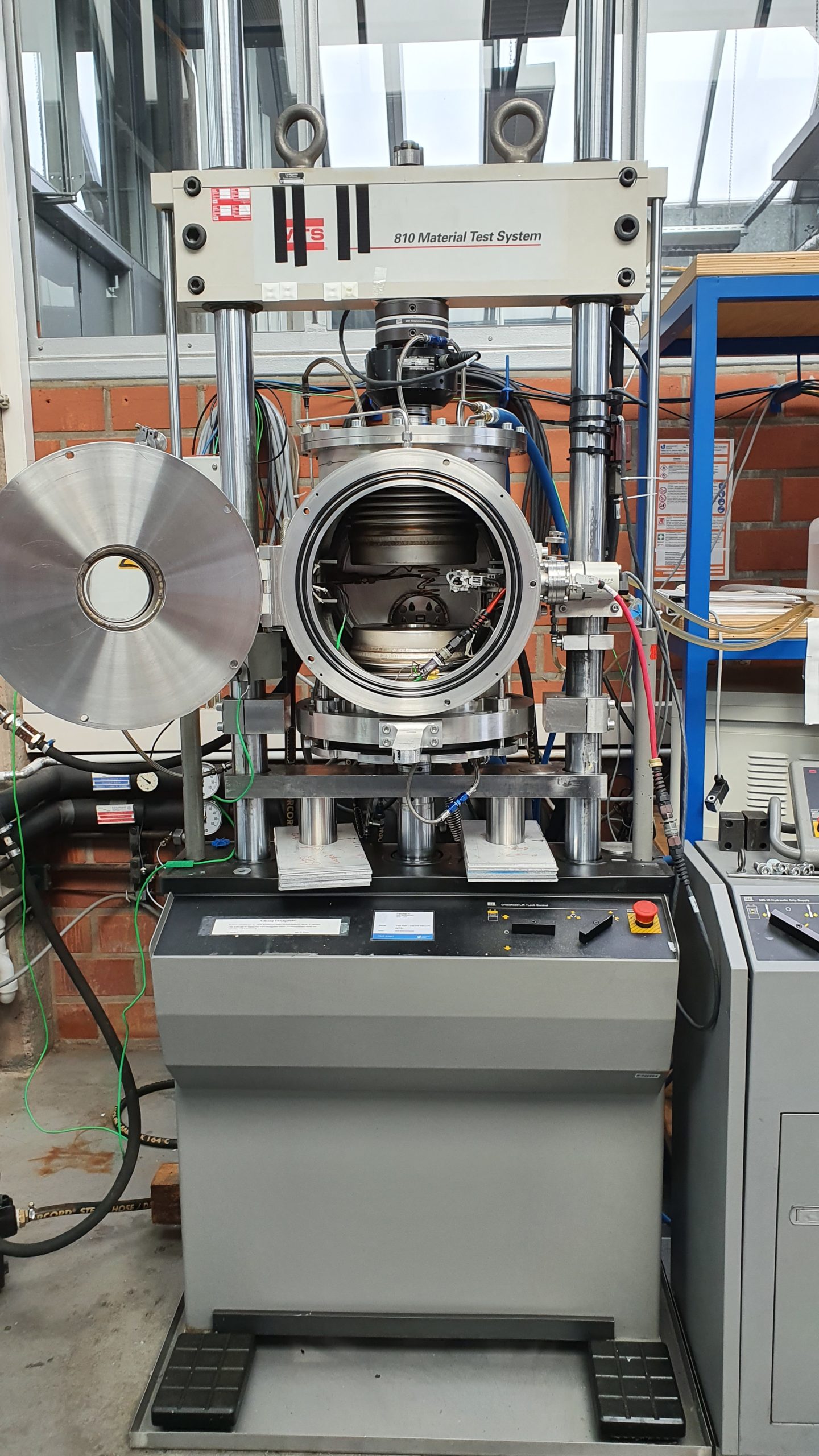

Hydropulse laboratory

Servohydraulic testing machines

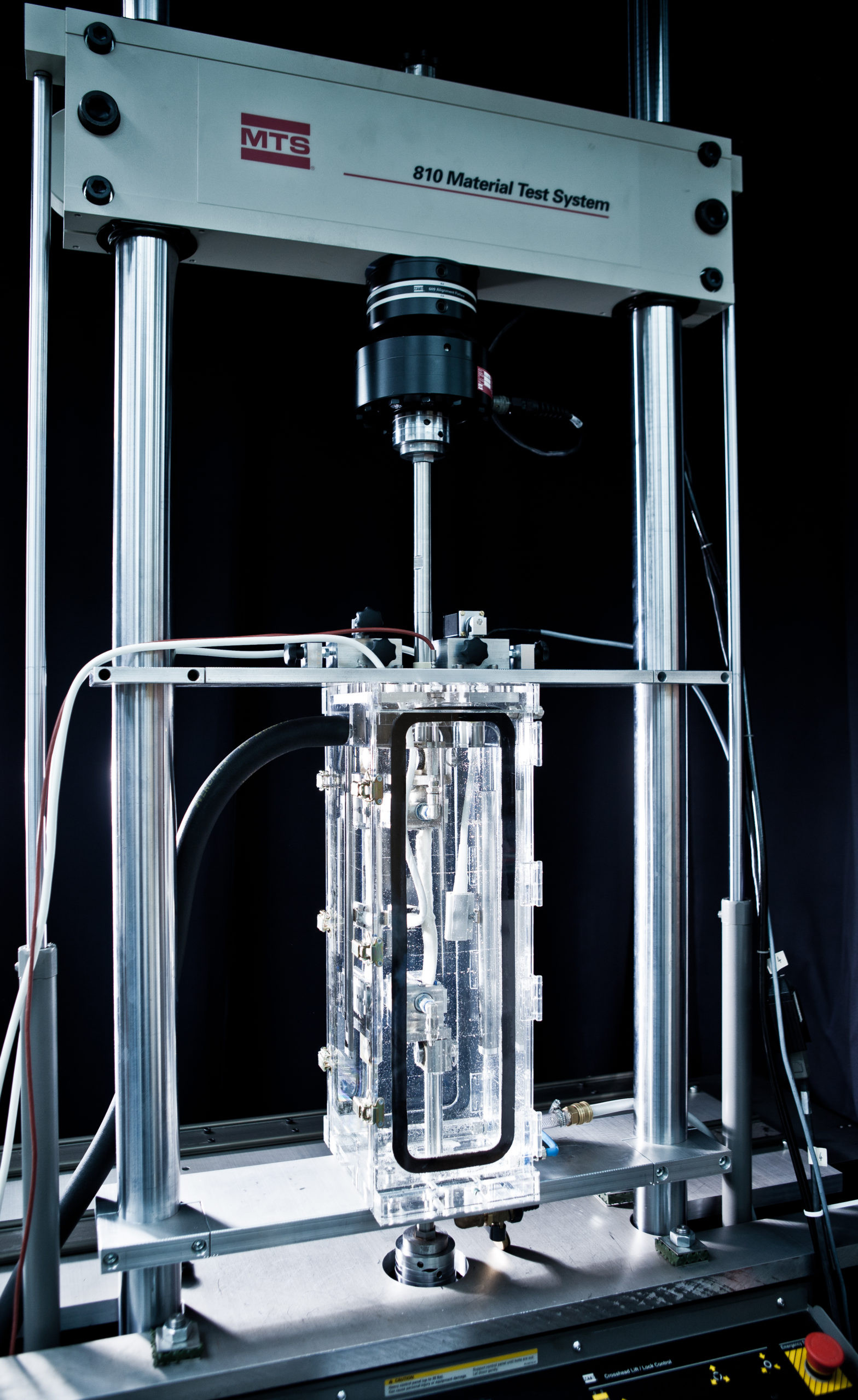

50 kN MTS 810 with induction heating

Give 100kN

100kN MTS 810 with vacuum system

Heat laboratory

Mechanical materials testing

Tensile testing machines

Equipment for routine materials science examinations

Creep test system

Sample preparation

general sample preparation

Separating machines:

Discotom

Cuto 1

Brilliant 210

Low

Wire saw

Embedding:

Cito Fix

Varidur 3000

Technovit 4000 and 5000

Thermoset blue

EpoMet

ProbeMet

SiC wet-grinding paper:

60, 80, 120, 220, 320, 400, 500, 800, 1000, 1200, 2400, 4000<br

Sanding polishing machines:

Jean Wirtz

Struers Rotopol-2

Wirtz

Polishing agents:

Alumina

OP-S

Diamond suspensions<br

Electrolyte:

Lectopol-5

Aktualisiert um 13:36 am 12. November 2021 von gk408